DIE Casting

“Elevate your manufacturing capabilities with ThingKraft’s premier Die Casting services. Experience precision, efficiency, and unmatched quality in every cast”

ThingKraft is Equipped with state-of-the-art gravity die casting machines to automate die movements, offering tilt pouring and hydraulic movement across up to four axes.

Discover the advantages of High Pressure Die Casting:

Unparalleled Precision

High pressure die casting is a cost-effective and reliable method for producing intricate parts with exceptional precision.

Superior Strength and Durability

Parts manufactured through this process exhibit remarkable strength, durability, and outstanding dimensional accuracy.

Enhanced Accuracy and Detail

Compared to other die-casting methods, high pressure die casting enables greater accuracy and detail, ensuring optimal results for your components.

Materials we work on :

Aluminium Alloys

Zinc Alloys

Explore the Dynamic World of High-Pressure Die Casting

Hot Chamber Process

Ideal for metals with low melting points like zinc and light alloys, the hot chamber die casting method employs a plunger to inject molten metal into molds. This rapid cooling process yields precise and durable parts.

Cold Chamber Process

Cold Chamber Process: With a focus on precision and efficiency, the cold chamber die casting system utilizes automated injection systems to introduce molten metal into the mold cavity. This advanced technique ensures consistent quality, enhanced accuracy, cost-efficiency, shorter cycle times, and elevated operator safety. Experience the pinnacle of die casting technology with ThingKraft.

Gravity Die Casting

Gravity Die Casting utilizes cast iron or steel molds, enabling the production of aluminum alloy castings with unparalleled precision and cost-effectiveness compared to sand casting.

Why Gravity Die Casting ?

This method ensures superior surface finish and mechanical properties, surpassing those achieved through sand casting.

One of the most notable advantages of gravity casting lies in its significantly lower tooling costs compared to pressure die casting. Additionally, the rapid chilling process employed in gravity casting results in excellent mechanical properties, while the non-turbulent filling ensures the production of heat-treatable castings with minimal porosity.

Discover the Versatility of High-Pressure Die Casting Applications

Automotive

From steering wheel hubs to engine blocks, high-pressure die casting ensures the production of robust and reliable car parts.

Medical

Critical medical devices and instruments benefit from the precision and reliability of high-pressure die casting.

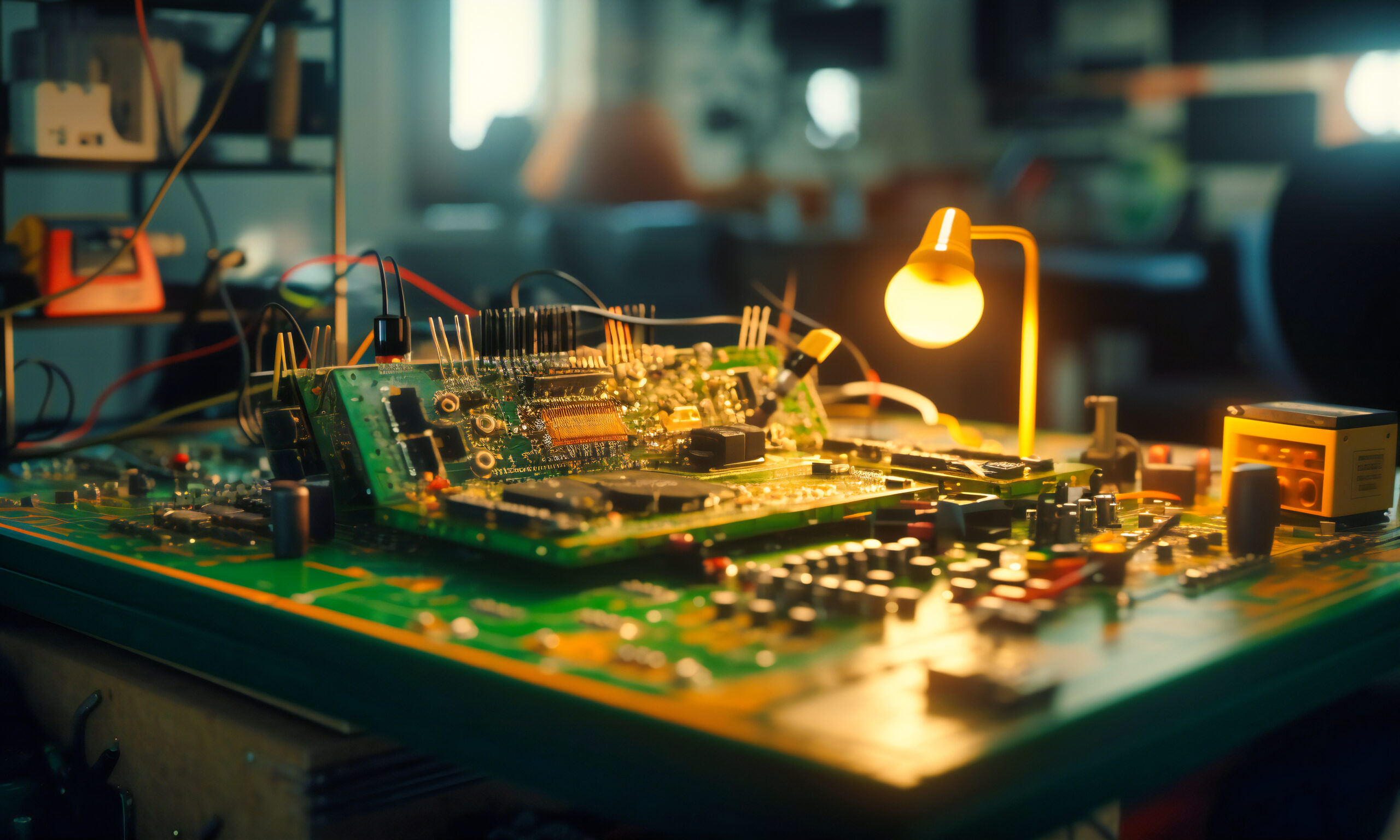

Electronics

High-pressure die casting technology provides the accuracy and intricacy needed for complex circuit boards and connectors’ housing.

Défense

High-pressure die casting is essential for military gun parts and defense equipment, ensuring strength and performance under pressure. Experience unmatched quality and reliability with ThingKraft.

Furniture

Die casting produces various fittings and connectors vital for furniture assembly, including joints, fasteners, frames, handles, knobs, hinges, and brackets.

Appliances

Precision and durability are crucial for appliance components, making high-pressure zinc die casting indispensable.

Other Casting Services at ThingKraft

Investment Casting

ThingKraft Manufacturing through its qualified partners offers a premium solution for intricate components with complex internal details or stringent weight requirements.

What are its advantages over alternative casting methods such as die casting or sand casting are numerous ?

Preserves Design Integrity

Facilitates Easy Tooling Alterations

Reduces Time and Costs on Alterations

Accommodates Various Component Sizes

Provides Fine Surface Finishes

Ensures Production to Precise Tolerances and High Accuracy

Maintains Uncompromised Part Integrity

Offers a Wide Range of Material Options

Lowers Tooling Costs Compared to Other Processes

At ThingKraft Manufacturing, we offer precision castings tailored to your exact specifications. Our castings come in a range of conditions, including meticulously heat-treated, finely machined, elegantly electropolished, and flawlessly mirror-polished, ensuring top-notch quality and exquisite craftsmanship in every piece

“Choose ThingKraft Manufacturing for adaptable and customized contract manufacturing services.”

Experience the pinnacle of manufacturing excellence with ThingKraft Manufacturing Technologies. Harness India's highly skilled professionals to elevate your product's quality and gain a competitive edge in today's cost conscious market landscape.

Address

Add 1: D 504 Varun, DSK Vishwa, Dhayari, Pune - 411062, Maharashtra.

Add 2 : Sr. No. 39, Jyotiba Nagar, Talawade, Pune - 411041, Maharashtra.

Phone

+91 9768-186-123

Mail ID

ldsouza@thingkraft.com

© 2024, ThingKraft. All rights reserved

Terms of use & Privacy policy